- mike@bitumenchem.com

- +86 15066607710

- Tongfa Avenue, Changqing District,Jinan

Location: Home > About Us > Company Page

bitumen emulsifier manufacturer

-High-performance bitumen emulsifiers help you produce high-quality bitumen emulsions

Introduction:

Founded in 2023, Jinan Bitumen & bitumen Chemical Co., Ltd. is a young yet highly focused export trading company specializing in bitumen emulsifiers, bitumen modifiers, and bitumen additives.

Our vision is to enhance

bitumen road construction by making it more environmentally friendly, efficient, and of the highest quality.

Advantages:

Brief advantages: (Let customers see our advantages and increase attractiveness)

1. ISO, CE and REACH certification

Each batch of products is strictly tested in accordance with ISO, CE and REACH standards, and the DCS system monitors the production process throughout to ensure high quality and reliability of products.

2. 15 years of bitumen processing research experience

Cooperating with well-known domestic universities, focusing on bitumen emulsification technology, and committed to solving key construction problems such as storage stability and adhesion.

3. Annual production capacity of 10,000 tons

With advanced production equipment and efficient processes, it meets the needs of large projects and ensures a continuous and stable supply chain and sufficient production capacity.

4. Samples delivered to the world within 10 days

Close to Qingdao Port, it responds quickly to international market needs, supports LCL/FCL transportation, and provides customers with an efficient delivery experience.

Application:

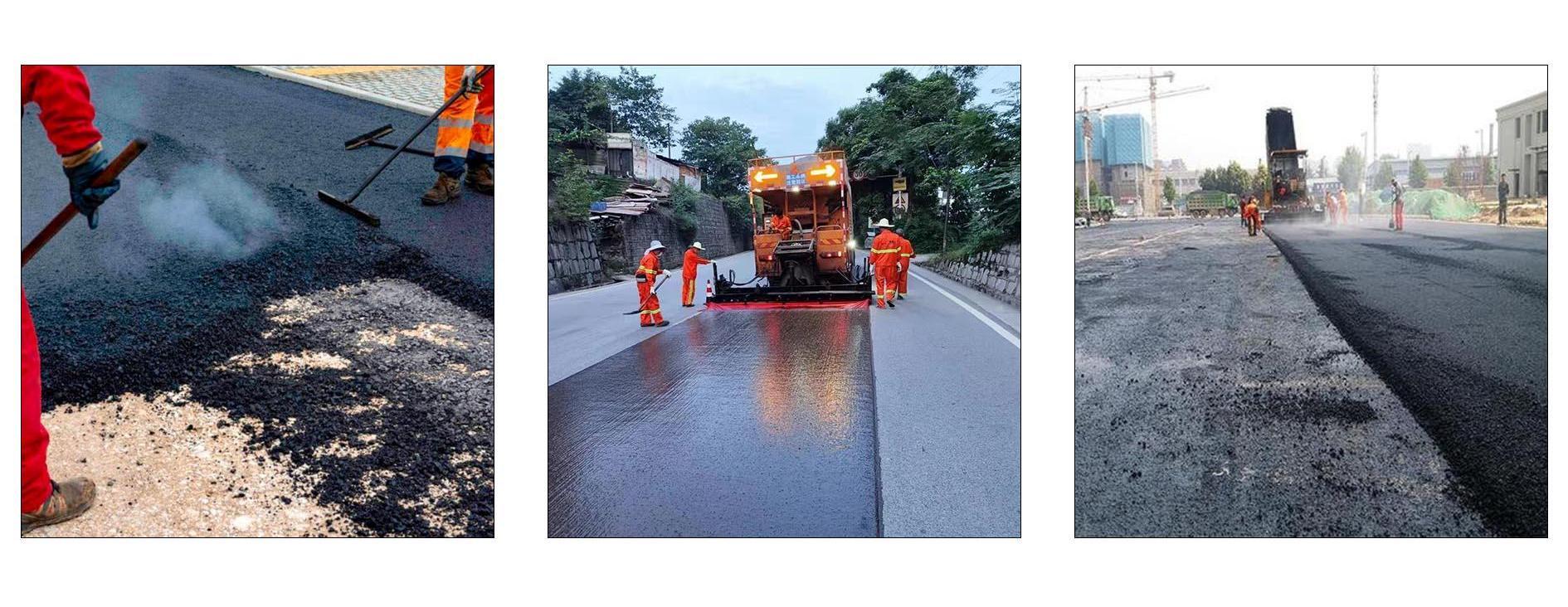

1.Highway construction and maintenance:bitumen emulsion production for prime coat, jacket coat and sully seal

Prime coat : a layer of permeable material, such as modified bitumen or emulsified bitumen, applied between the newly laid base and the surface layer to enhance interlayer bonding and prevent moisture from penetrating into the base.

Jacket coat: a rapid setting or slow setting emulsified bitumen sprayed between two layers to ensure good bonding between new and old pavement or different bitumen layers. It provides an immediate bonding effect and helps improve overall structural stability.

Slurry Sealis amixture of finely graded aggregate and bitumen emulsion applied as sealand wearing surface to bitumen or concrete roads,parking lots and airports.Slurry sealswaterproof and seal thesurface from water ingress and deterioration andprovide askid resistant,smooth running surface.

Brief description of bitumen emulsion production: bitumen emulsion is made by dispersing hot molten bitumen into water containing emulsifier. This process includes preparing raw materials (bitumen and emulsifier), heating bitumen, preparing emulsion, mixing the two at high speed to form a stable emulsion, and finally cooling and storing. Each application may require adjusting the specific formulation of the emulsion to suit its specific requirements.

2.Modifiers for modified bitumen and bitumen emulsions

2.1. Modifiers in modified bitumen

Modified bitumen is the addition of specific modifiers to ordinary bitumen to improve its high-temperature stability, low-temperature crack resistance, durability and adhesion.

Polymer Modifier:

SBS (styrene-butadiene-styrene block copolymer):

Features: SBS is one of the most commonly used polymer modifiers, which can significantly improve the high-temperature stability and low-temperature ductility of bitumen and reduce the occurrence of ruts and cracks.

Application: Suitable for highways, heavy traffic sections, bridges and other projects that require high road performance.

SBR (styrene-butadiene rubber):

Features: SBR can improve the elasticity and adhesion of bitumen and enhance its fatigue resistance. It is especially suitable for roads in cold areas and can effectively prevent low-temperature cracking.

Application: Commonly used in cold areas or road sections with large temperature differences.

2.2. Modifiers in bitumen emulsions

Bitumen emulsions are suspension systems composed of bitumen, emulsifiers and water, with good construction performance and environmental protection characteristics. In order to further improve the performance of bitumen emulsions, the following types of modifiers are usually added:

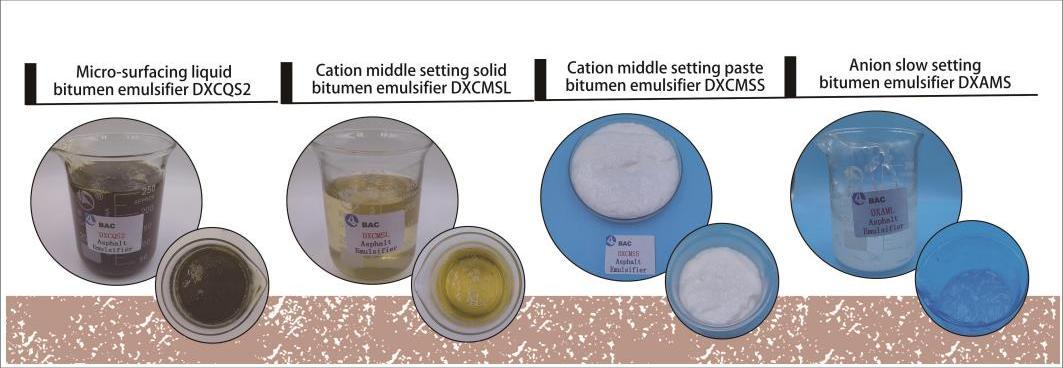

Emulsifiers

Cationic emulsifiers:

Features: Cationic emulsifiers can make bitumen particles positively charged, enhance their adhesion with alkaline aggregates (such as limestone, dolomite, etc.), and improve the stability of the emulsion.

Application: Suitable for the preparation of most bitumen emulsions, especially in projects using alkaline aggregates.

Anionic emulsifiers:

Features: Anionic emulsifiers can make bitumen particles negatively charged, suitable for acidic aggregates (such as granite, basalt, etc.). It can improve the storage stability and demulsification speed of the emulsion.

Application: Suitable for road projects using acidic aggregates.

Nonionic emulsifiers:

Features: Nonionic emulsifiers are not charged, have good chemical stability and wide applicability. It can be mixed with other types of emulsifiers to adjust the performance of the emulsion.

Application: Suitable for projects with special requirements on emulsion performance, such as those requiring high stability and rapid demulsification.

Adhesion promoter:Modifier for bitumen mixture that can form a physical effect with the aggregate surface, or rely on its special chemical structure to form a chemical bond with the aggregate surface, which can enhance the adhesion between bitumen and aggregate. It is usually used to improve the water stability of bitumen mixture.

By adding different modifiers, the properties of modified bitumen and bitumen emulsion can be significantly improved to adapt to different construction requirements and environmental conditions. Choosing the right modifier can extend road life, improve driving safety, and reduce maintenance costs.

3.Chemical Additives for Bitumen Concrete

Adhesion promoter:

Used to enhance the bonding between bitumen and aggregate, especially in humid environments, to prevent water-induced peeling.

Modifier:

Including SBS (styrene-butadiene-styrene block copolymer), SBR (styrene-butadiene rubber), PE (polyethylene), etc., used to improve the temperature sensitivity, flexibility and durability of bitumen.

Emulsifier:

Enables bitumen to be evenly dispersed in water to form a stable emulsion, which is convenient for spraying and paving during construction.

Stabilizer:

Helps maintain the stability of bitumen mixture during storage and transportation to prevent stratification or hardening.

4.Other bitumen additives

Anti-rutting agent is a series of high-performance bitumen modifiers developed from thermoplastic resin/elastomer through blending and compatibilization and component enhancement. By strengthening the modified bitumen, it can greatly improve the high-temperature performance of the bitumen mixture, and at the same time, it can effectively improve Water damage resistance and low temperature performance of bitumen mixtures. The product has the characteristics of good anti-rutting effect, excellent comprehensive performance, environmental protection, no pollution and convenient construction. It is suitable for various grades of highways such as highways, municipal roads and other bitumen pavements. According to product performance and usage requirements, it can be subdivided into different models.

5.Building waterproofing: production of bitumen-based waterproof coatings

Bitumen-based waterproof coating is a waterproof material widely used in construction and infrastructure. It is mainly composed of bitumen, solvents, fillers, thickeners, emulsifiers, preservatives and pigments.

Its production is briefly described as follows:

Prepare raw materials: Accurately weigh bitumen, solvents, fillers and other additives according to the formula.

Heating and mixing: Heat the bitumen to a suitable temperature (usually 100-180°C), then add the solvent and other ingredients in sequence, and continue to stir to ensure uniform mixing.

Add other ingredients: Gradually add fillers, thickeners, emulsifiers (for water-based paints), preservatives, mildew inhibitors and pigments, and continue to stir until a uniform coating is formed.

Filtering: Remove undissolved large particles through a fine mesh or filter to ensure fine coating.

Cooling and packaging: After cooling, seal and package for storage and transportation.

Features:

Excellent waterproof performance: Provides reliable waterproof protection.

Good weather resistance: Adapts to various climatic conditions.

Environmentally friendly choice: Water-based products reduce VOC (volatile organic compounds) emissions.

Convenient construction: Easy to apply and apply.

bitumen-based waterproof coatings are widely used in the field of building waterproofing due to their high cost-effectiveness and easy construction. With the advancement of technology, they are constantly developing in the direction of more environmentally friendly and high performance.

Application Introduction:

| prime coat | jacket coat | Chip seal | Sully seal | Micro surfing seal |

|  |  |  |  |

| The prime coat uses cation slow setting bitumen emulsifier. Our non-acid-adjusted series can help customers solve the problem of difficulty in purchasing hydrochloric acid. Acid-adjusted bitumen emulsifier solves the problem of difficult storage | The jacket coat uses CRS bitumen emulsion. DXCRSL1 is a liquid emulsifier, which is more convenient to use DXCRSS is a solid emulsifier with high effective content and lower addition amount, which can be used for emulsifying SBS modified bitumen | Chip seal uses CRS or CMS bitumen emulsions CRSS can increase the viscosity CMSS emulsifiers do not need to add hydrochloric acid, which is very convenient to use and saves costs | There are 2 types of slurry seals: Slow opening traffic, with a wide range of compatibility with stone. Fast opening traffic type, no need to add hydrochloric acid and fast opening traffic time | It has a wide range of stone compatibility. It can also have sufficient mixing time with stones with strong activity. Open traffic time is within 2 hours |

Contact Us:

Every inquiry from you is very important to us. We will:

Give a quick response within 24 hours;

Provide personalized customized solutions to meet your specific needs;

One-on-one follow-up by professional team members to ensure smooth communication;

All submitted information is strictly confidential to protect your privacy.

Inquire now and enjoy exclusive discounts!

Please fill in the following information according to the prompts so that we can serve you more accurately:

Name:

Company Name (optional):

Email: Required

Contact Number: Required

Fields/Products of Interest:

Specific Demand Description: